This Article describes how to Grease or "Pack" WWII Jeep axle wheel bearings. Applies to 1942,42,1943,43,1944,44,1945 Jeeps models

|

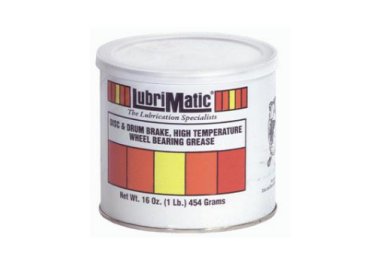

1. Packing your bearings is a simple process to do yourself. Whether you are using your existing bearings or a new set of bearings, you will need some grease and a set of bearings. A good bearing grease label should state: High Temp rating, resists softening, superior load-carrying capability, corrosion inhibitors, anti-wear and water resistance claims. Most General Purpose greases will fall short of temp limits, load bearing |

|

2. To start with, when packing your bearings you want grease to be packed in all of the bearings nooks and crannies as shown with arrows. |

|

3. Have a towel to wipe your hands available... Take a chunk of bearing grease in your left hand, Start at the edge of the lump of grease and squeeze it through a little at a time until the grease pops from between the rollers on the top side, then turn the bearing a little to work on a new area. This pushes the grease to inner areas you can't see. Use a press and slide motion like you're trying to scrape the grease off your hand. It goes faster that way. |

|

4. When you're washing the bearings out, don't EVER spin them with the air hose. It will mark the races because there's no lube, and I also have seen the rollers fly out of the cage and cause injury. |