Many WWII Plastic Jeep steering wheels are weathered with cracks from being outside for many years. This article shows how to repair your WWII Jeep steering wheel.

|

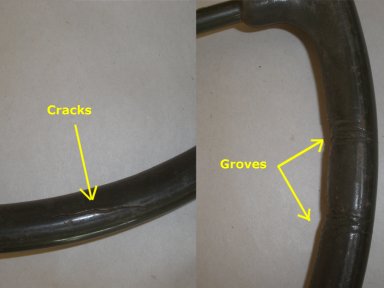

1. Over the years it is very common to see original steering wheels with cracks or damage. This article will help show you how to fix damaged, plastic WWII jeep steering wheels. |

|

2. First, you want to have a few items handy. You want to have the following handy before starting: |

|

3. Damaged steering wheels usually have two issues. 1) steering wheel cracking 2) Indents or Groves. We will repair both types of problems |

|

4. To start, we found a donor steering wheel that is beyond repair. We want to use the plastic off this steering wheel, in order to match the plastic on the steering wheel to repair. |

|

5. Next, put the section of steering into a vise, and cut groves 90 degrees from the others. The plastic will start falling off center section. Place these chips into a small container for organization. |

|

6. When you have all of the plastic chips off the metal band, then place them in a container so you do not lose them. |

|

7. Next, we want to smash these pieces of plastic up because we will need to desolve them later. In this case, we placed the plastic chips in a contained area on a small press. |

|

8. We review the smashed pieces, and make sure there are no lumpy pieces left. Once done, then put the smashed pieces of plastic back into your container. |

|

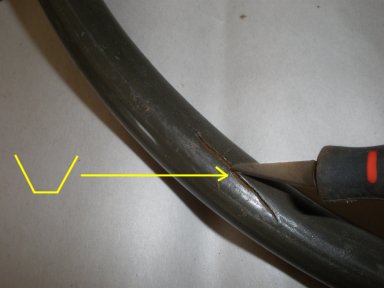

9. Next, we want to work on the cracked area. Take an xacto knife and cut the edges of the split into a V shape. The V shape will make a better fill area when we apply the replacement plastic. |

|

10. On the groved areas, use a hacksaw to cut deeper groves into that area, it may take a few grooves as shown. This will allow the replacement plastic a better area to adhere to. |

|

11. Next, we prepare the smashed plastic by cutting the smashed plastic into a small canister (like olives, or chilies). I usually keep small cans and jars for purposes like this laying around. Cut these pieces of plastic into very small chips. |

|

12. You only need to cut up a few sections of plastic, just enough to start disolving. Here you see is plenty of plastic available to repair the dings in this steering wheel. |

|

13. Next, add about 4-5 tablespoons of acetone to you container with the small chips. The acetone should cover the pieces in the container, and give them about 3-4 minutes to soak. |

|

14. In preparation of filliing these area, take a Q-tip and dip it in the acetone, and touch the areas so that the plastic will get soft prior to applying the disolved plastic. |

|

15. Next, start stiring the acetone with the plastic chips. The small chips will disolve into an epoxy type of material, but will take alot of stiring. |

|

16. Keep stiring and smashing the pieces against the edge. It is kinda like making pancakes and getting rid of the lumps. You may need to add a little acetone as you are mixing. Once the lumps are out, you are ready to apply. |

|

17. Now the plastic should be disolved and feeling like epoxy glue. Scoop it out with the stick and apply it to the cracked area, and the other areas you are trying to fill |

|

18. Note: gravity will pull this liquid into the steering creveses, so you may need to look to see if you need to apply a 2nd or 3rd coat. The mixture will dry in about 15-20 minutes, unless you add more acetone. |

|

19. Now let the patched areas dry over night. The next steps will be sanding and preparing the steering wheel for a restoration look. |

|

20. THIS ARTICLE IS STILL IN PROGRESS... |

|

21. |

|

22. |

|

23. |

|

24. |

|

25. |